Eni in Italy has launched its new HPC4 supercomputer. With a peak performance of 18.6 Petaflops, the HPC4 cluster from Hewlett Packard Enterprise quadruples the Company’s computing power, making it the world’s most powerful industrial system.

Eni in Italy has launched its new HPC4 supercomputer. With a peak performance of 18.6 Petaflops, the HPC4 cluster from Hewlett Packard Enterprise quadruples the Company’s computing power, making it the world’s most powerful industrial system.

HPC4 is an important achievement in Eni’s digitalization process,” said Eni CEO Claudio Descalzi. “Installed at the Eni’s Green Data Center, the new HPC4 supercomputer will ensure a very high level of data processing and storage capacity. The system is able to host the entire ecosystem of algorithms developed internally by Eni.”

The new hybrid HPC cluster is built on 1600 HPE ProLiant DL380 nodes, each equipped with two Intel 24-core Skylake processors (totaling more than 76,000 cores) and two NVIDIA Tesla P100 GPU accelerators, all connected through a high-speed EDR InfiniBand. The new system will be working alongside a high performance 15 Petabytes storage subsystem.

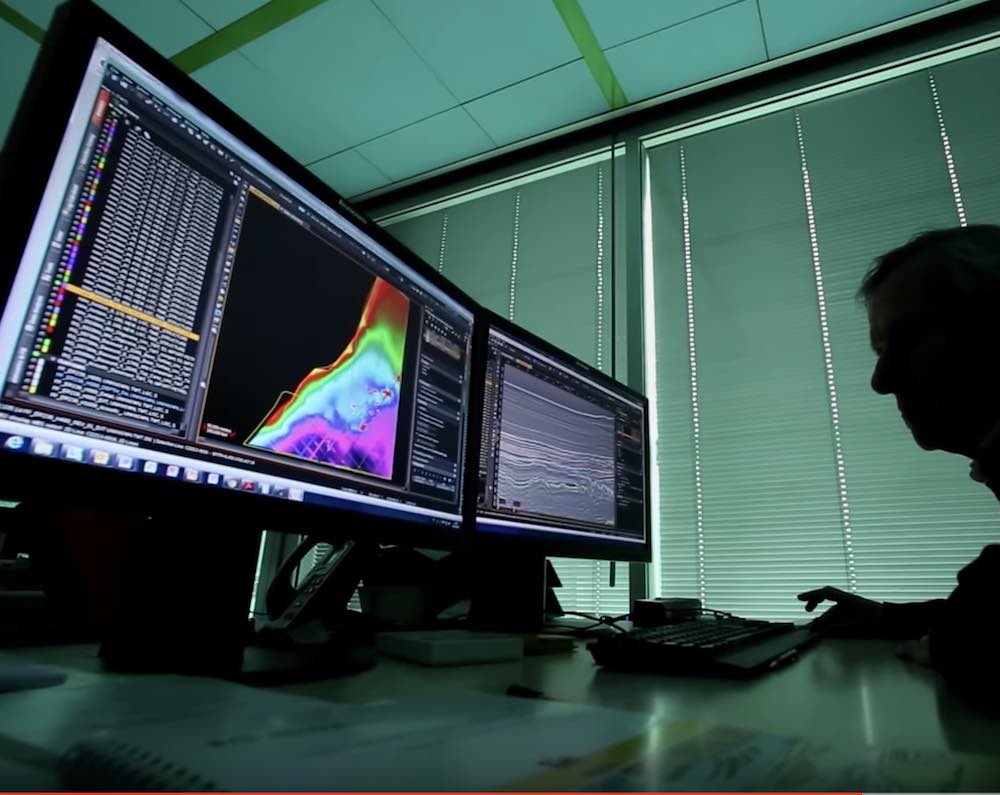

Eni’s Green Data Center’s supercomputers (the HPC3 and the new HPC4) provide strategic support to the company’s process of digital transformation across the entire value chain, from the exploration and development phase of oil and gas reservoirs, to the management of the big data generated in the operational phase by all our productive assets (upstream, refining and petrochemicals).

With HPC4 we are tracing the path for the use of exascale supercomputers in the energy sector that could revolutionize the way in which oil&gas activities are managed. In line with Eni’s sustainability policy, Eni’s Green Data Center as well as the new HPC4 have been engineered to ensure the maximum level of energy efficiency in order to minimize CO2 emissions and operating costs”.

Eni’s supercomputing infrastructure operates on the basis of an extremely advanced and complex proprietary ecosystem of algorithms, created and developed by Eni, and based on the company’s own experience and know-how. In particular, HPC4 will support the execution and evolution of Eni’s leading edge suite of 3D Seismic Imaging packages, as well as advanced Petroleum System Modeling together with state of the art Reservoir Simulation algorithms and optimization of production plants.

Eni’s supercomputing infrastructure operates on the basis of an extremely advanced and complex proprietary ecosystem of algorithms, created and developed by Eni, and based on the company’s own experience and know-how. In particular, HPC4 will support the execution and evolution of Eni’s leading edge suite of 3D Seismic Imaging packages, as well as advanced Petroleum System Modeling together with state of the art Reservoir Simulation algorithms and optimization of production plants.

The investments devoted to reinforcing the supercomputing infrastructure and the development of algorithms are a significant part of Eni’s digital transformation process,” said Descalzi. “We can store and process enormous quantities of data for geophysical imaging, the modeling of oil systems and reservoirs, in addition to using predictive and cognitive computing algorithms for all our business activities. These technologies will enable us, on the one hand, to accelerate and make the entire upstream process more efficient and accurate, reducing risks in the exploration phase and, at the same time, giving us a significant technological advantage, but also to increase the level of reliability, technical integrity and operability of all our productive plants, while minimizing operational risks, with benefits both in terms of safety and environmental impact. In our industry it is increasingly important to be able to process ever-increasing amounts of data, ensuring more accurate and faster results.

Sign up for our insideHPC Newsletter